2 Case Studies - Dissolving Tank Explosions - USA 2016 & 2017

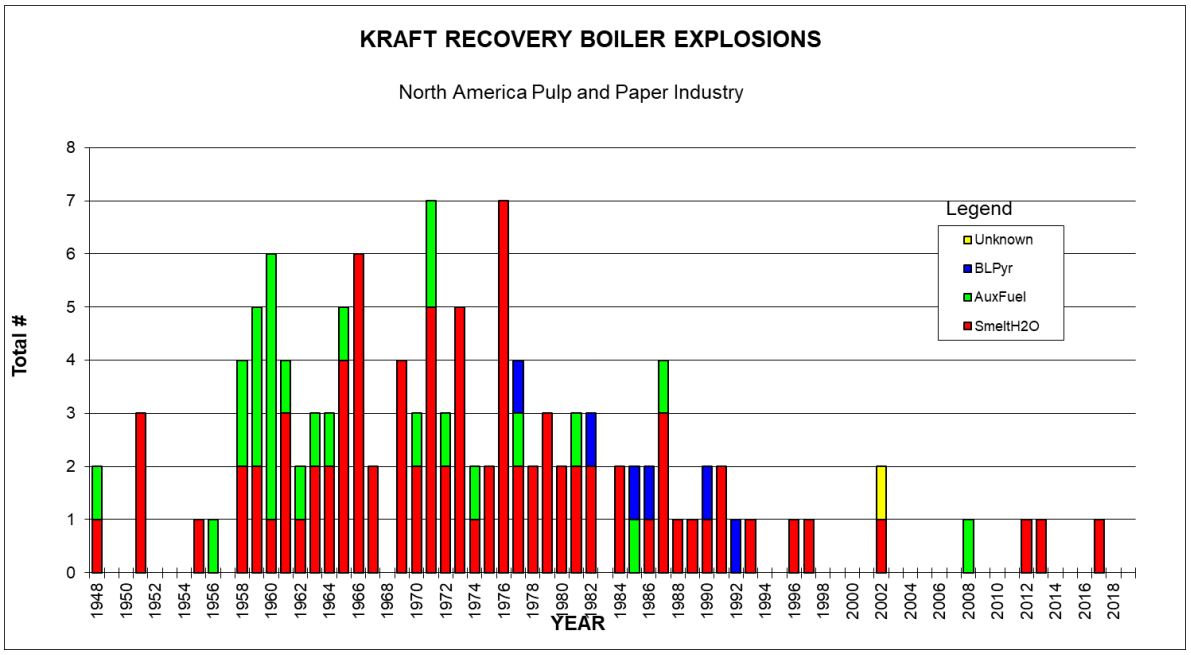

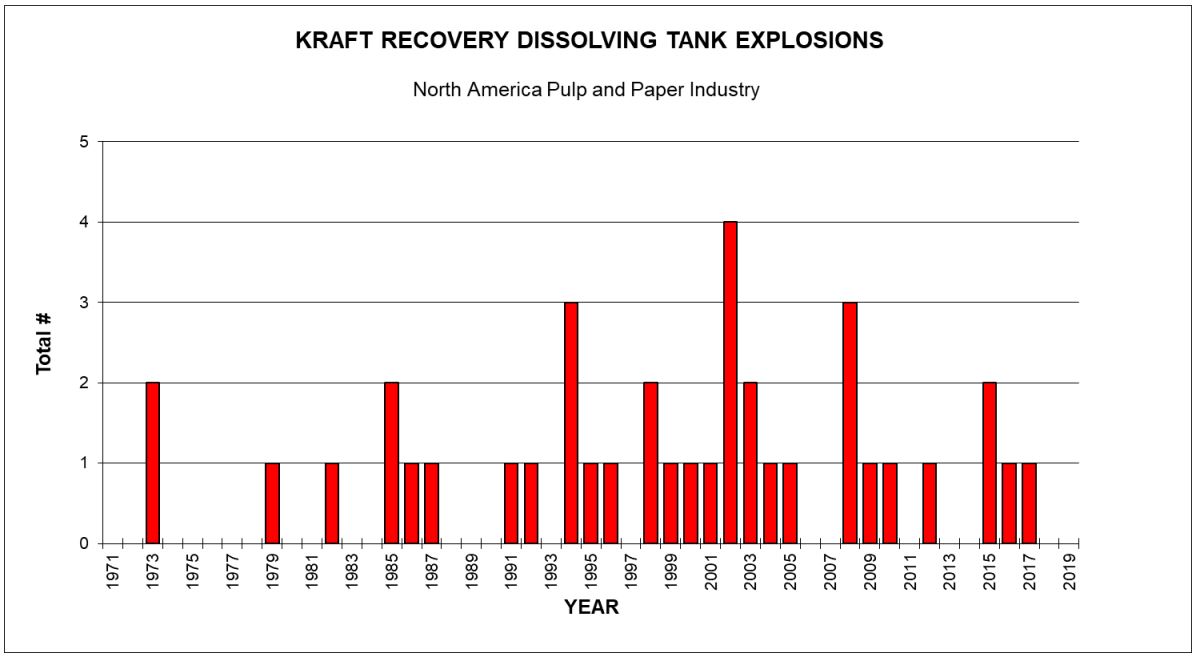

Last time we explored a recovery boiler explosion that happened in Canada. And while tube leaks are the major cause of smelt water reactions in recovery boilers, dissolving tank explosions pose the same if not even higher risk than tube leaks. BLRBAC reports that recovery boiler explosions have been significantly reduced in the past several decades. The dissolving tank explosions however draw a different picture. For example, since 2000 there have been 6 recovery boiler explosions reported in the North America, but a total of 20 dissolving tank explosions.

The following charts are taken from BLRBAC meeting minutes.

Explosions in the dissolving tank usually happen because of one of four specific reasons.

- Increased smelt flow that overwhelms the shatter jets and results in smelt water reaction.

- Low dissolving tank level cannot keep up dissolving the incoming smelt resulting in pooling of the smelt in the dissolving tank and subsequent smelt water reaction.

- Loss of agitation either due to a loss of agitators or shatter jets or both.

- Too high concentration of the green liquor causes a crystalization and thus impedes dissolving of additional smelt coming in.

Today, we are going to look at the first cause. So let's have a look at two specific cases of a dissolving tank explosion and what can we learn from it.

Case 1: 2017 - USA - From failed air port rodder to dissolving tank explosion

Downtime: 5 days 6 hours

Sequence of Events

2:45am - A port rodder shorts out on a recovery boiler. The breaker didn't trip because a 15 amp vs. a 10 amp breaker was used by mistake. This however causes PDC to trip instead of the port rodder breaker.

With the PDC tripping, OFF goes the ID fan which causes Master Fuel Trip. The important fact here is that the boiler trips unexpectedly with full bed. It really does not matter why it tripped in this case.

Subsequent to the trip, a leak in the feedwater system was found and being repaired which added to the downtime and cool down period.

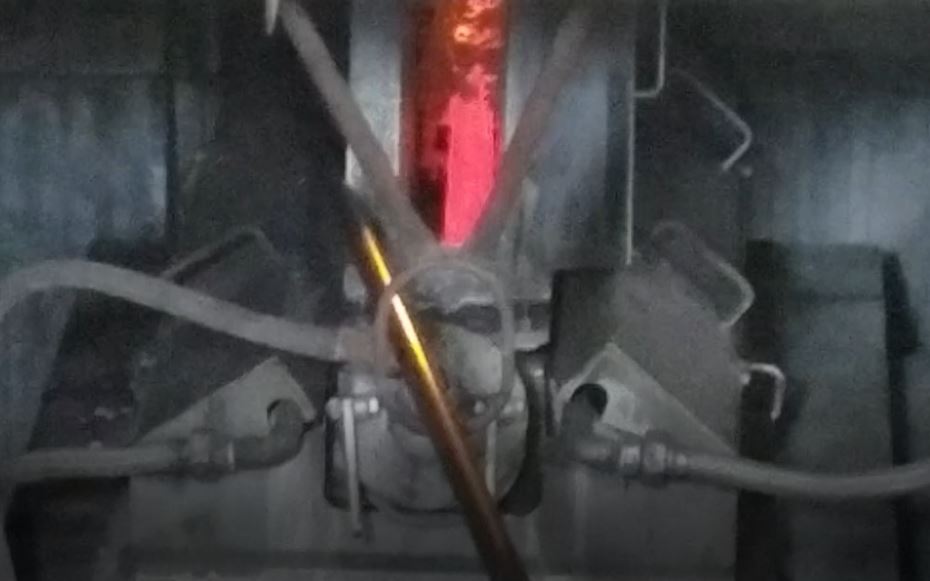

5:25am - Operators occupied with the repairs noticed that the char bed is cooling down and smelt spouts are getting closed up. They try to keep them open by inserting rods but are not successful due to the hardening smelt.

6:10am - Normal start up begins. First igniter in the boiler.

6:37am to 10:38am - Three start-up burners are put into operation

11am - Boiler online on auxiliary fuel.

12:30am - Boiler ready to accept liquor per permissives. However all smelt spouts are still plugged and as such liquor was not introduced into the boiler. Operators keep trying to open the spouts with rods and sledge hammers. Bed camera shows a pool of smelt little higher than normal, but not excessive.

2:41pm - Spouts cannot be manually open. It is decided to put one liquor gun in for short period of time in order to temporarily increase heat flow and melt the hardened smelt around the spouts. Liquor gun was used only for 41 minutes and the location was chosen to direct the heat towards the spouts.

5:05pm - One of the spouts opens up resulting in a rushed smelt flow from build out pool inside the furnace. The flow overwhelms the shatter jets and smelt runs fully into the dissolving tank.

5:05pm - Dissolving tank explosion occurs. Operators evacuate the area and initiate a master fuel trip.

Extent of Damage

Luckily, no personnel were injured during this incident. The force of the explosion caused the tank anchor bolts to fail and moved the entire tank about 8 inches (20 cm). Due to the movement additional piping misalignment occurred. Total downtime: 5 days 6 hours.

Case 2: 2016 - USA - From Trip to Explosion

Sequence of Events

Sunday 11pm - Unexpected power outage causes a recovery boiler to trip with full char bed.

Tuesday 11pm - Boiler back online on auxiliary fuel. Smelt spouts partially open.

Wednesday 7pm - Effluent treatment issues cause operators to do a controlled shutdown of the boiler. Boiler down again with full bed.

Thursday 8:30pm - Boiler back online on auxiliary fuel.

Friday 2:50pm - Smelt spouts partially open and decision is made to put liquor in.

Friday 3:09pm - Smelt spouts observed plugged and thus liquor pulled out of the boiler.

Friday 4:20pm - Spouts are being cleared with torches. One of the spouts partially opens up and has a small smelt flow going through. Decision is made to put liquor into the furnace.

Friday 4:30pm - Liquor gun put into the boiler. Operator on the smelt deck observes a smelt flow filling up the ENTIRE smelt spout. Dissolving tank went quiet followed by 5 explosions, 3rd being the loudest. Operator on the liquor gun floor hears the explosion and pulls the liquor gun back out. Last explosion activated master fuel trip and dissolving tank explosion damper opened up.

The damage and the downtime were not reported.

Conclusion and takeaway

Just like in both of these cases of a dissolving tank explosion, this happens when overwhelming the capacity of the tank to accept smelt at a rate it was coming in. This happens when a recovery boiler trips with a full bed and is forced to stay down and thus the bed cools down solidifying the smelt and plugging the spout openings. Restarting the boiler becomes tricky and risky.

While auxiliary fuel helps melt the smelt around the smelt spouts and thus causing them to open up, prolonged auxiliary fuel firing without open smelt spouts is dangerous as it causes all molten smelt to pool and be ready to be released once a spout opens. And this was the case in both boilers above.

In both cases, the operators were well aware of the risks and took steps to open up the spouts manually or using additional heat within the boiler. However, the magnitude of the molten smelt pooled and ready to be released was underestimated. So in both cases, one of the spouts finally opened up and the release of the smelt caused an explosion.

Recommendations

Each recovery boiler operating company should establish baselines and procedures for restarting a recovery boiler with full char bed after a prolonged cool down period.

If a recovery boiler trips with full or partial bed and cannot be restarted within a short period of time special steps should be taken.

Some companies have a procedure for restarting a boiler that tripped with a full bed and had a downtime of more than 6 hours by requiring a cooling and water washing of the bed.

Otherwise, spouts should be attempted to open up manually with rods or torches. Sledge hammers can be used but are discouraged due to potential damage to the floor tubes.

Auxiliary fuel can be started to help melt the smelt and open up the spouts. The location of burners used should be decided so that they direct the heat towards the spouts.

However, prolonged significant auxiliary fuel firing without smelt spouts open and a full bed is highly discouraged.

Train your operators to recognize these situations and take the proper steps.